Our Journey

Wick physics meet 3D design. DeCera offers two complementary lines: scented wax sculptures for display, and lattice candles engineered to burn cleanly downward.

Even burns need a straight wick. In classic candles the wick should run vertically to avoid tunnelling and uneven melt pools. That constraint limits adventurous shapes — so we approached it from two angles.

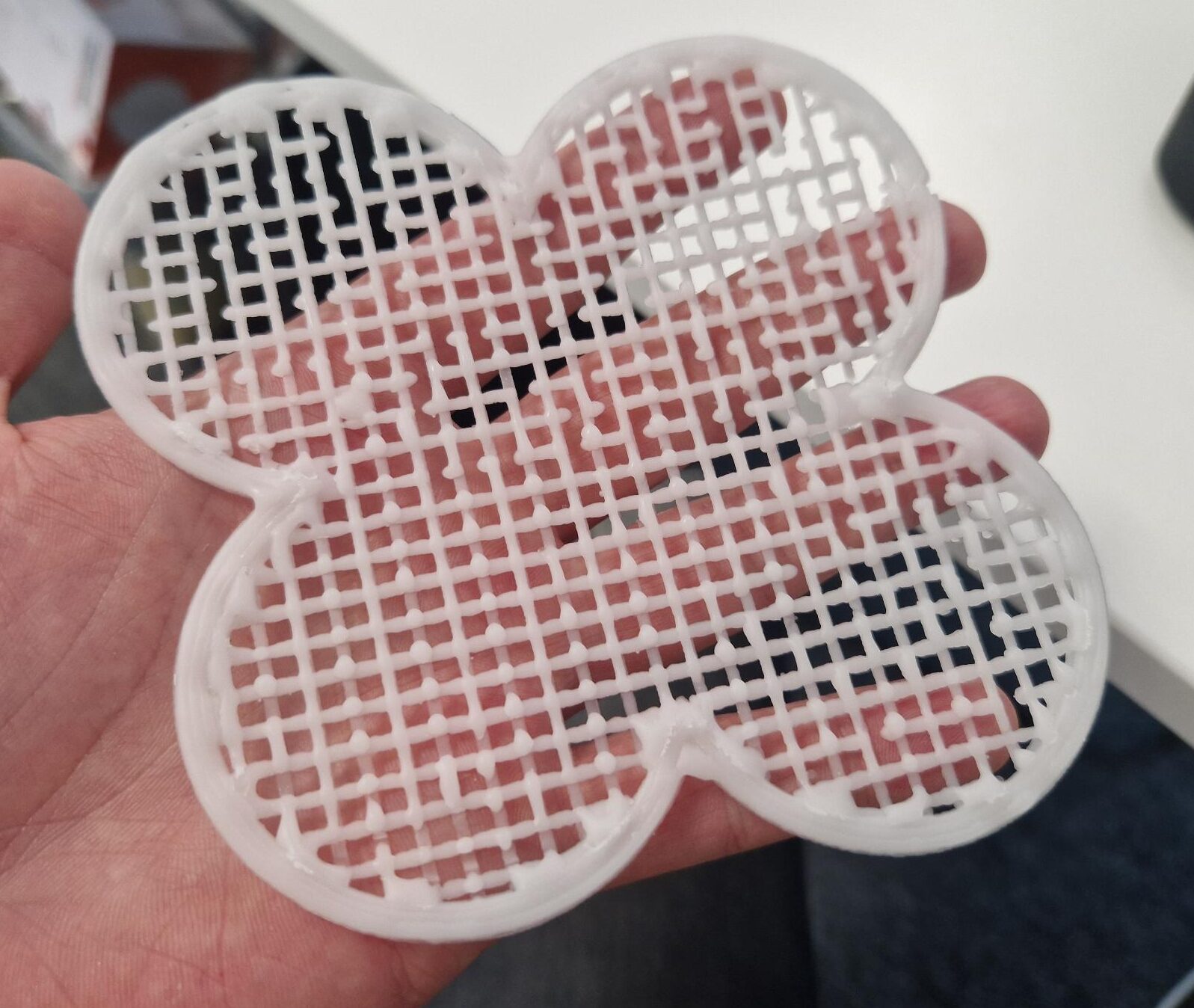

Scented Wax Sculptures are wick-free pieces designed to be admired. They offer a strong cold throw from the moment you unbox, and can be gently warmed to release additional fragrance — no flame required. Lattice Candles keep a vertical core wick for a clean, downward burn, while the outer 3D lattice casts intricate light and shadow as the candle melts.

Four Leaf Clover Prototype, June 2025

Origin & Vision — a gift unique to them

DeCera began with a simple ambition: to give everyone a gift that is unmistakably theirs. Three shifts make this possible today:

- Modular manufacturing — 3D printing enables short runs and rapid iteration without tooling.

- Accessible generative design — AI-assisted modelling lowers the barrier from idea to form.

- Consumer appetite for personalisation — people want objects that reflect their stories.

We pair those trends with proprietary, printable wax formulas developed for detail fidelity, surface quality and reliable burn behaviour where relevant.

Problem & Discovery

Candles burn evenly only when the wick runs straight down. We embraced that constraint by creating two products: wick-free scented sculptures for enduring display, and burnable lattice candles that preserve a vertical wick path whilst showcasing intricate geometry.

Modelling & Structure

For sculptures, forms prioritise silhouette, surface quality and fragrance diffusion (strong cold throw with optional gentle warming). For candles, models include a central wick channel and engineered lattice thicknesses that hold shape cold, then reveal patterns as the candle burns.

Print Tuning & Materials

Printable blends: our proprietary wax recipes are tuned for flow, layer adhesion and edge crispness. Printer profiles: temperature, flow rate, layer height and orientation are iterated to minimise artefacts and support marks, and to deliver predictable melts on the candle line.

Finishing, QA & Packaging

Sculptures are hand-finished for crisp edges and a satin feel. Candles undergo test burns to validate a steady downward melt and even pool around the core wick. Each piece is inspected and packaged to protect edges and lattice features in transit.

Progression

Refinements included temperature/flow tuning, layer height adjustments, revised support strategy and orientation changes.

Always burn candles on a heat-safe surface, away from draughts and out of reach of children/pets. Never leave a burning candle unattended.